Well, it's that time - I thought I would step up to the mic and tell you the sad tale of my abysmal failure. lol

You may remember that about a month ago,

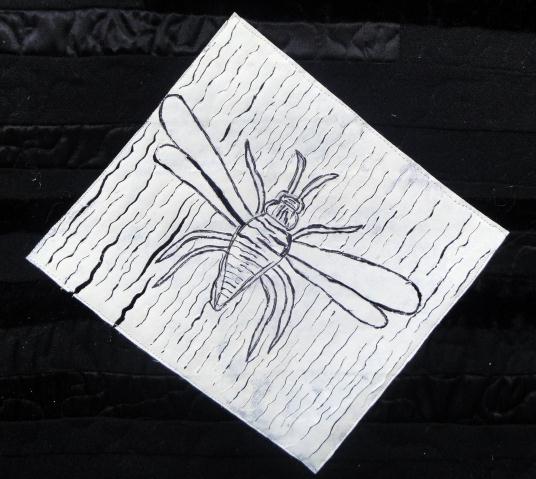

I had an idea to see if I could do something similar to Riusuke Fukahori's resin work in textile. I was totally sure it would work, so after a errant step into encaustic, I shook off my paw and happily skipped off to get some resin.

The first layer turned out really well, and I was pretty excited. The only problem I found was that it didn't provide enough depth to create the look I wanted, so I knew I'd have to do 3 or 4 more layers before I could start laying the animals out. But, so what, right? Fukahori has to do like, a

gajillion layers of resin - what's 15 or 20 layers for me?!?

The next layer turned out equally well, although it took longer to dry. The first layer took about 12 hours, the second layer about 18 hours. (You see where this is going, right? I didn't. I mean, I suppose I would have, if I'd actually thought about it, but I just kept blithely going on...)

But I soon realized it's inherent problem was built right in. It was a

glazing resin. I was already through my 3rd box and my first layer of animals was only covered half way, and the drying time between layers was taking 5 or 6 DAYS.

This pic was taken at day 5 - and as you can see, it's nowhere near dry.

It was time for me to re-assess.

I'd have to use another 3 boxes to finish the piece, and at this advanced drying time, it would take me months to finish the piece - not to mention, at $36/box, this was becoming quite an expensive enterprise.

Enter my new hero, CASTING RESIN.

At only $22 for the medium size, this was clearly going to be a far more economical enterprise, and it promised a drying time of only two hours! I was practically dancing with excitement to get it done and show you the result.

I mixed according to directions, carefully poured it over my piece (made a comment to myself along the lines of "Wow. This stuff is WAY more smelly than the glazing resin") and then cleared a space to set it to dry.

I began tidying up my room to start another project and became aware that the "chemical" smell was becoming quite unbearable. I opened windows throughout the floor that my sewing room is on, made sure all the doors were open, and got to work on the next project.

About 1/2 an hour later, BSP came downstairs and "yelled" "Are you trying to KILL us??!! WHAT IS THAT SMELL???!!!" I went upstairs and discovered that the smell was all through the house. Oh-oh! I opened up some more doors and windows, took a break to have a diet Coke and chat with BSP and then went downstairs again where I was practically knocked over by the incredibly powerful smell of the resin.

With apologies to the

Day Supervisor, There was nothing for it but to move the project outside.

Unfortunately, I knew it would be ruined. It had to have a mininum temperature of 70 degrees to set well and this was Ontario, in March. (eep!) We'd been having warmer temperatures than usual, but 70 was a lot to ask, especially at night.

I put it outside, covered it to protect it from anything that might fall on it and left it. I mean LEFT it.

I knew it was going to be ruined and I wasn't psychologically prepared for that, so I left it there for a couple of weeks. I finally picked it up about ten days ago, brought it down to my sewing room and uncovered it.

::sigh:::

So, until it's summer weather here, that's the end of my resin experiments. However, having assessed the time, cost and effect, I may not do this again.

Here's how it all worked out, re expenses:

1. Encaustic wax, damar resin and electric frying pan $160

2. 3 boxes of glazing resin @ $36/each $108

3. 1 can of casting resin $22

4. Silk and other fabrics, batting, fusible, thread $20

GRAND TOTAL: $310

THREE HUNDRED AND TEN DOLLARS!!!! (I'm glad BSP doesn't read my blog. lol)

Now, to be fair, I'll give the the encaustic stuff another whirl (I've already got an idea for something I want to try), so we can take $160 off that total price tag. And our learnings have taught us that glazing resin is not the answer, so we'll just need casting resin in the future, and for a piece this size (8 x 10) I'd probably only need two cans, so that's $44 plus the supplies for the quilt itself at $20, so all told, it's $66 rather than $310.

But still....

$66 for an 8 x 10 piece is quite an investment. And as you know, I usually work in the 20 x 30" or 30 x 50" size, so that price would probably be more like $150 which is getting a up there again. I mean if I spend $150 on a quilt, I should be able to sell it for at least twice that much. But I've never sold an art piece before and I don't know what the market will bear...but I don't think it'll be $300 for an 8 x 10" piece!

And, the truth of it is, if you look at that first pic up there where everything was going so well, it looks fine, but it doesn't look

awesome. I mean, the addition of the resin made you go "Oh. Cool." but it didn't really

add anything to it.

Except weight. A LOT of weight. lol

By the time we got to the point where the piece was ruined, it was already about 3 pounds. And that was prior to the next couple of layers being added on - don't forget - this was just layer one of the animals; there was supposed to be another layer of animals and then another layer of trees - this thing would have weighed about 10 pounds, possibly more (!) by the time it was done, and it was only 8 x 10"!!

So, expense + weight + "not that cool after all" = I probably won't do this again.

But, nothing ventured, nothing gained, right? Stay tuned for my next adventure!

And have a wonderful holiday weekend whether you're celebrating Easter, Pesach or just some time off!

I'll be golfing. :)

%2B%2Bthree%2B(c)%2BKit%2BLang%2B2014%2Blutradur.jpg)

%2BKit%2BLang.jpg)

+2012+Kit+Lang.JPG)

+2012+Kit+Lang.JPG)

+2012+Kit+Lang.JPG)